Case Study

Compressed Air Management System for Energy Savings

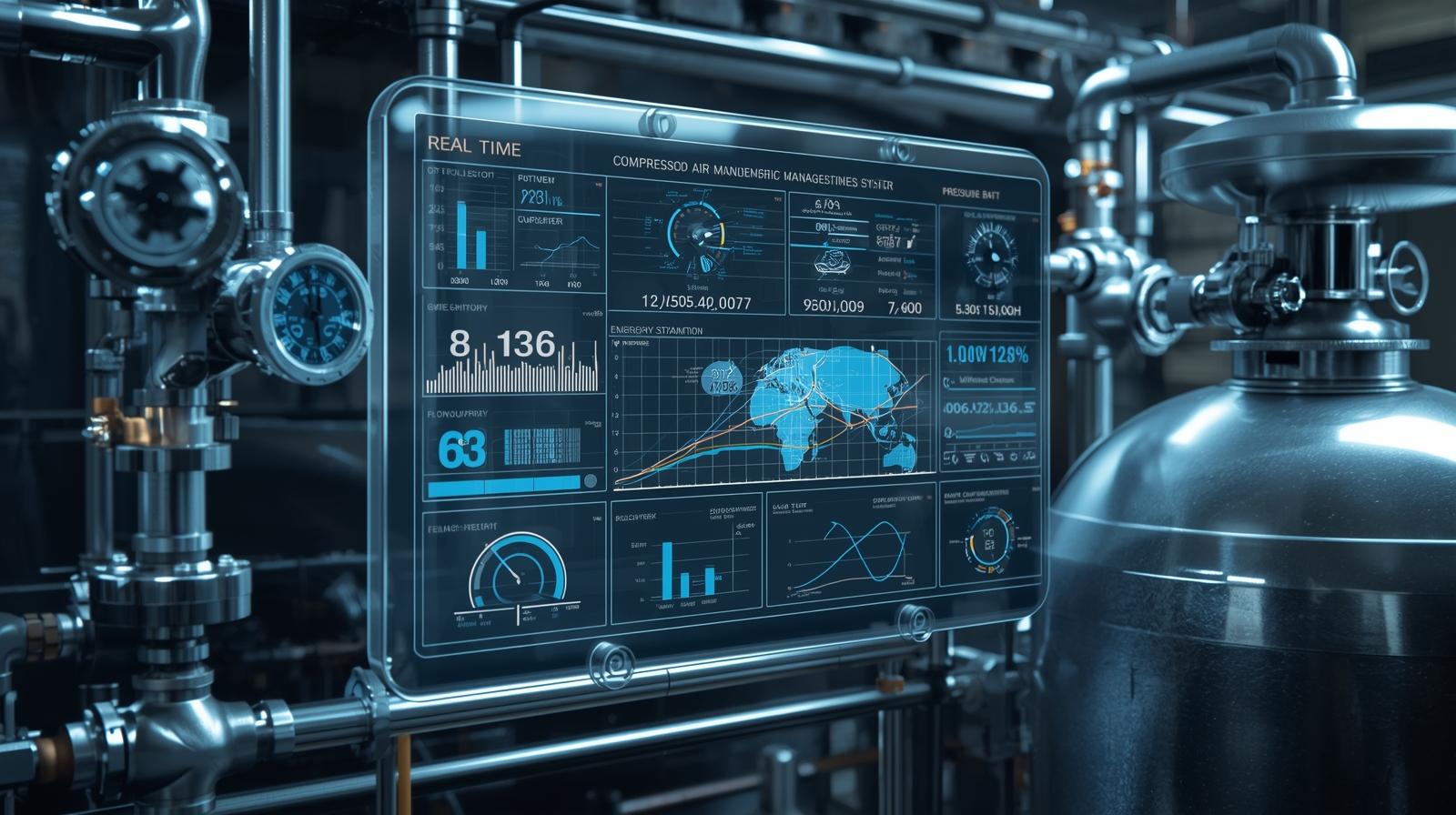

Our CAMS solution enabled a leading manufacturing client to optimize their compressed air network, detect leakages, and reduce power consumption—resulting in significant energy savings and improved operational efficiency.

Project Highlights

- ✔ Client’s compressed air system faced frequent pressure drops and high energy bills due to leakages and inefficient load sharing.

- ✔ No real-time monitoring or visibility into compressor operations and distribution network.

- ✔ Installed IoT-enabled flow meters & pressure sensors across air distribution lines.

- ✔ Implemented AI-based leakage detection and predictive load scheduling.

- ✔ Automated load balancing between multiple compressors for optimum efficiency.

- ✔ Established centralized monitoring & control of all air lines directly from the compressor room.

- ✔ Installed IoT-operated valves for remote control, safety interlocks, and optimized air distribution.

- ✔ Integrated with a real-time online dashboard for monitoring pressure, flow, and energy consumption.

- ✔ Reduced unexpected downtime and ensured stable pressure across production lines.

Result: The client achieved a 25% reduction in energy costs, improved production reliability, and eliminated wastage from leakages—contributing to sustainable and cost-efficient operations.