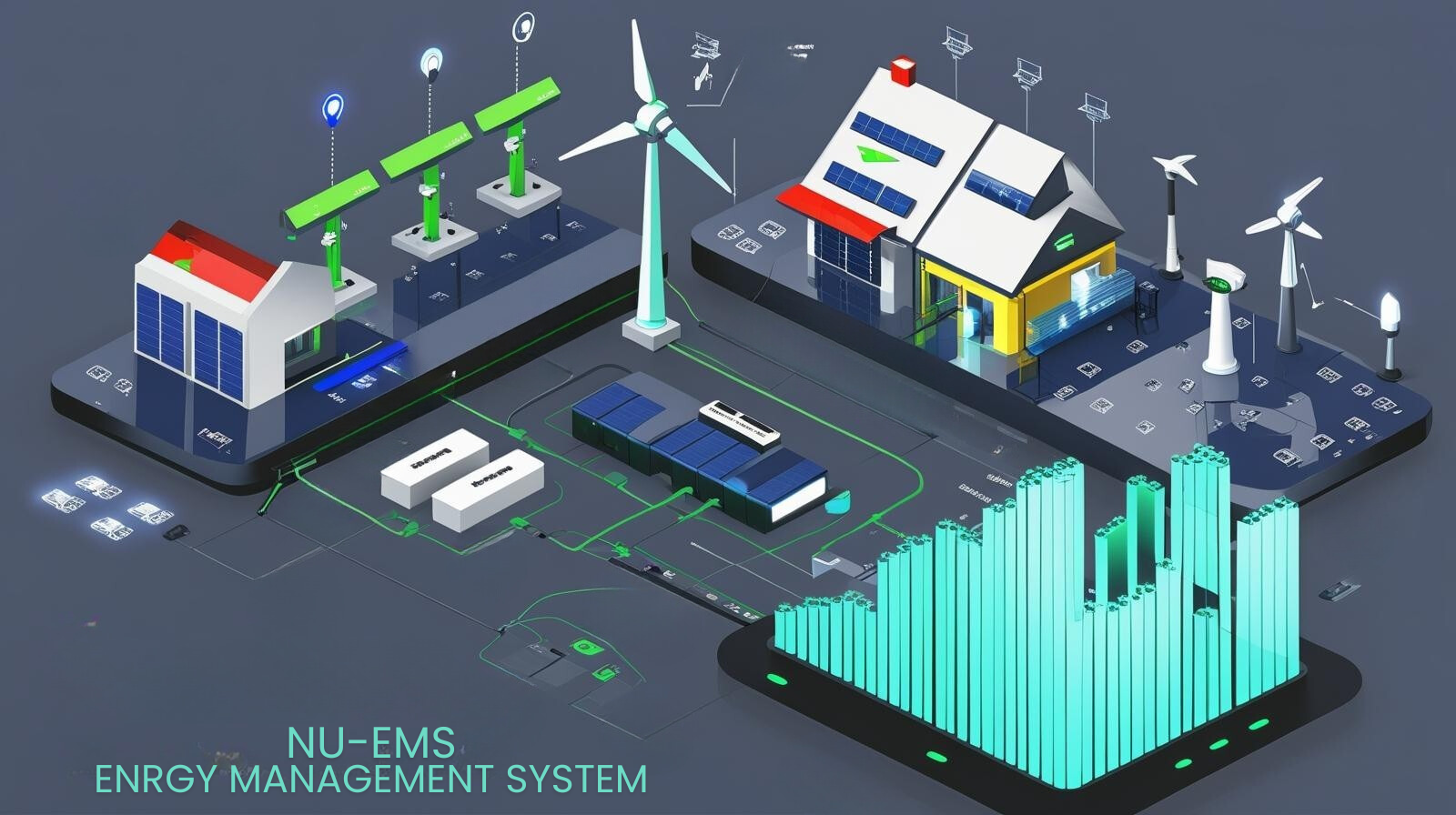

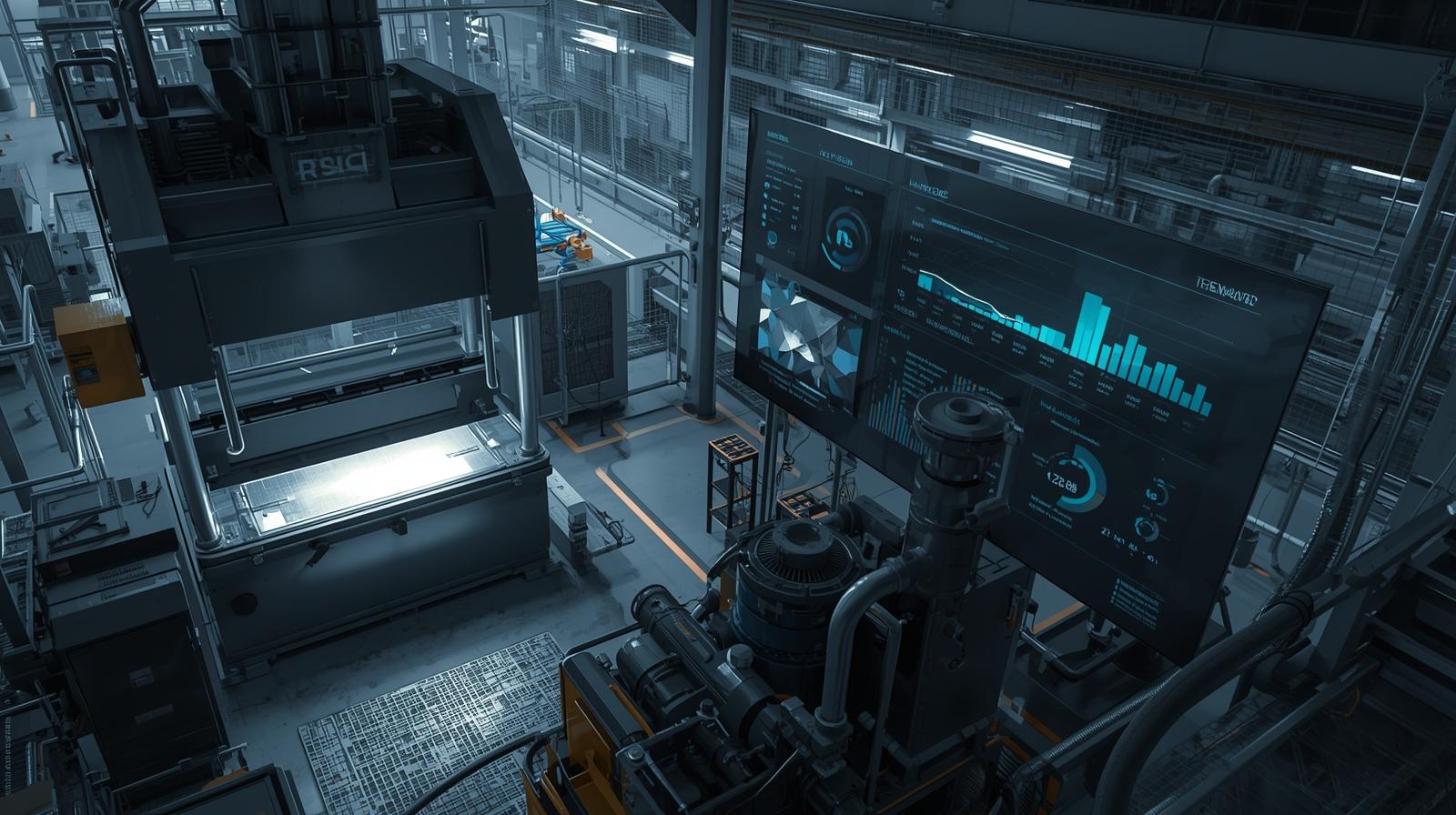

Nu Tek Power Controls and Automation, we merge the power of Industrial Internet of Things (IIoT) with artificial intelligence to turn raw industrial data into real-time insights and smarter decisions. Our platforms connect machines, processes, and people, enabling predictive maintenance, energy optimization, and operational excellence for Industry 4.0 leaders

Bring Us Your Toughest Industrial Challenges — We Deliver Solutions.

At Nu Tek Power Controls & Automation, we turn IIoT + AI into real business results. From downtime reduction to energy optimization and process modernization, our consulting transforms challenges into competitive advantages.

Since day one, we’ve been delivering smart automation and data-driven solutions that keep industries running at peak performance. With IIoT, AI, and deep domain expertise, we turn challenges into lasting successes.

+91-9739141053

We bring together energy specialists, manufacturing process engineers, automation experts, and AI experts to design intelligent systems tailored for your industry. Our solutions modernize existing machines, upgrade process lines, and introduce new innovations to solve your most complex challenges. With our integrated expertise, we deliver measurable improvements in efficiency, cost savings, and sustainability. By combining deep industry knowledge with modern digital technologies, we help businesses transition into smarter, data-driven operations.

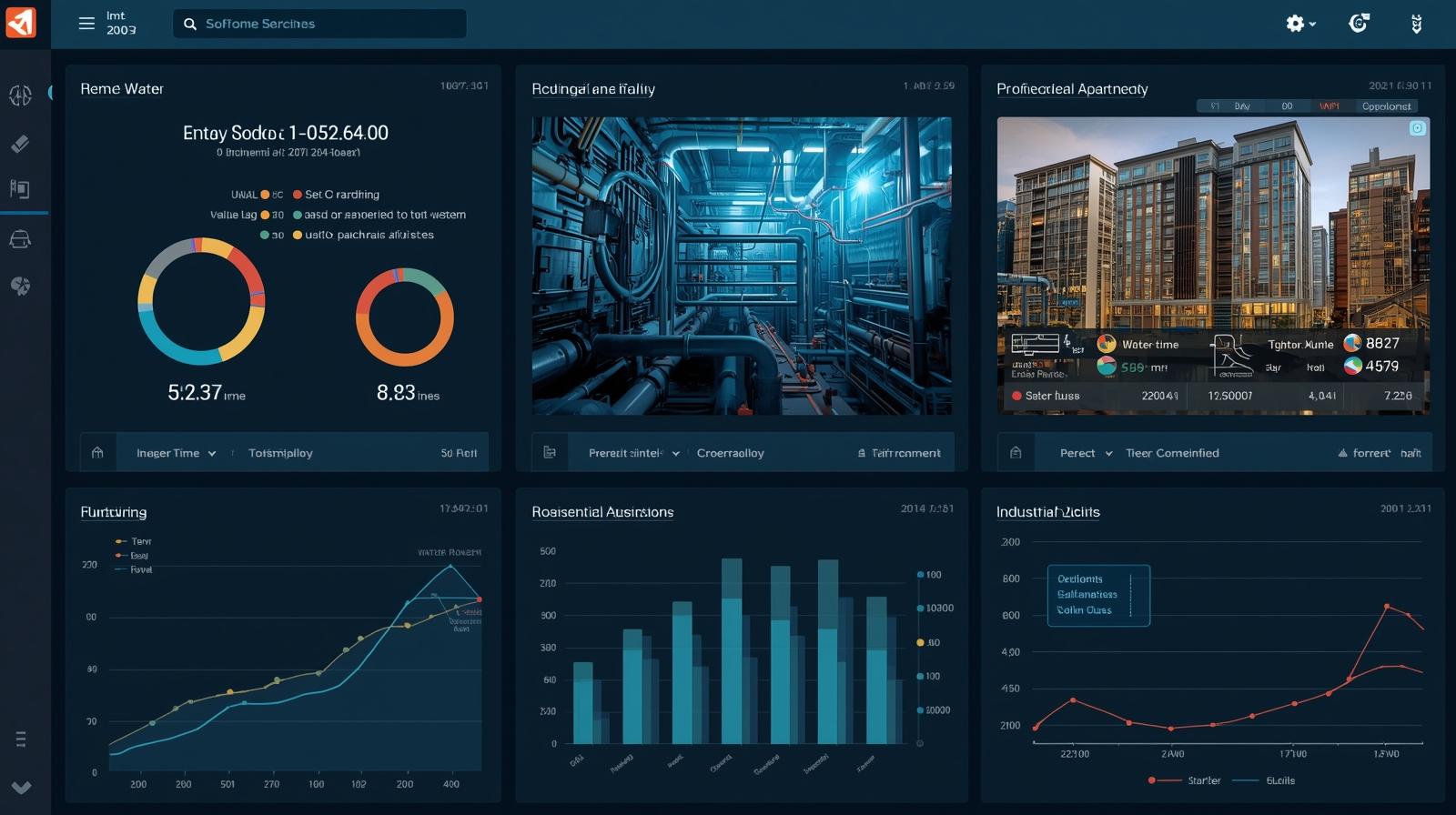

Real-time monitoring of consumption, demand peaks, and power quality. Benchmark, target, and verify savings with automated reports and alerts.

Learn More

Measure consumption, pressure, and quality. Detect anomalies and leakage, and ensure compliance with sustainability targets.

Learn More

Track line speed, bottlenecks, and rejects. Improve throughput with live OEE dashboards and downtime analytics.

Learn More

Track generation, PR, inverter status, and string-level anomalies. Maximize output with fault detection, predictive analytics, DG synchronization, hybrid operation, energy forecasting, and performance benchmarking.

Learn More

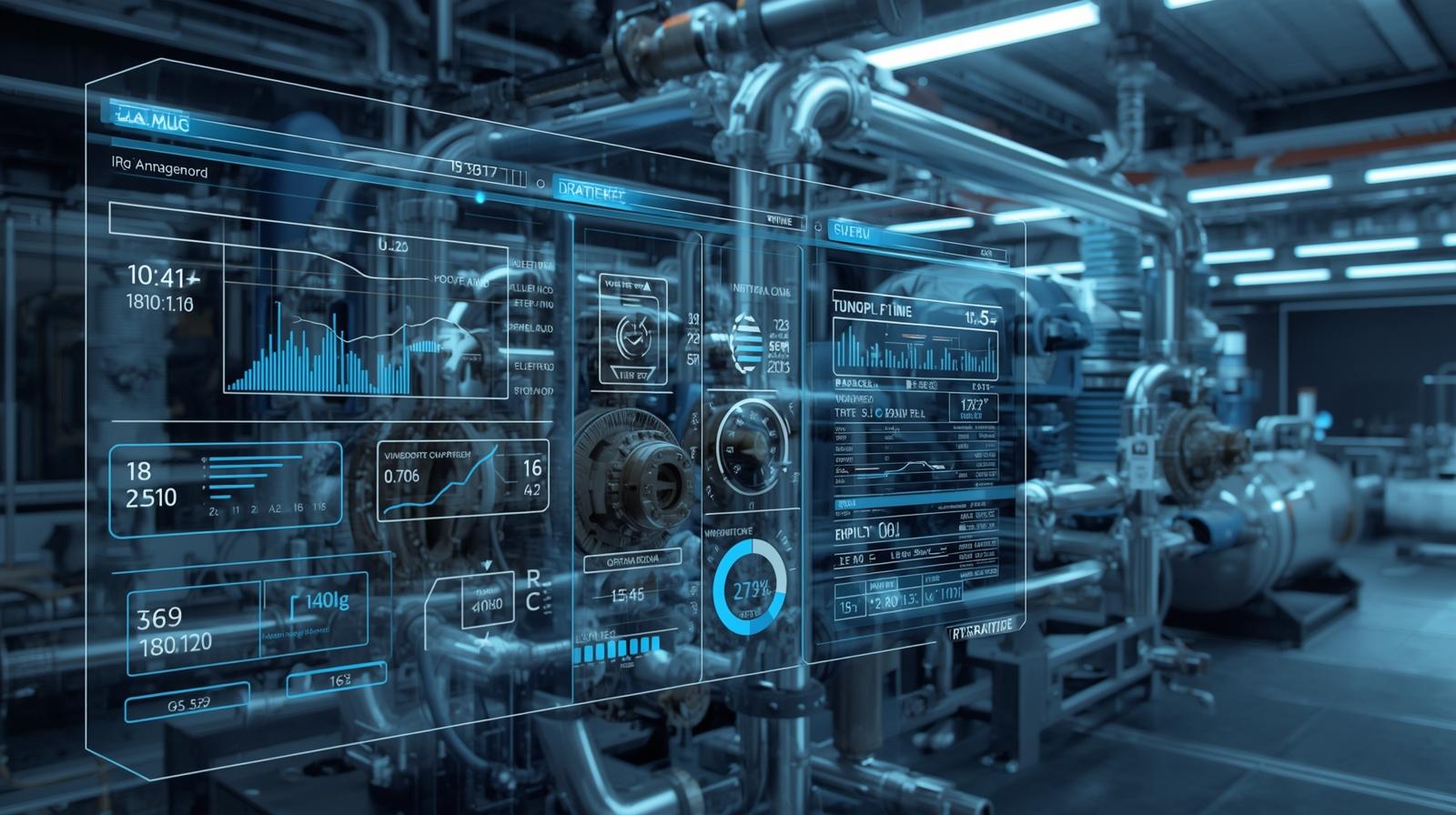

Continuous visibility of temperatures, flow, and pressure. Improve heat-transfer efficiency and safety with alarms and trends. Ensure reliability and minimize downtime with predictive insights.

Learn More

Monitor compressors, pressure, and flow. Detect leaks, optimize loading/unloading, and cut energy costs with performance analytics, real-time dashboards, alerts, and sustainability insights.

Learn More

Control temperature profiles, cycles, and energy usage. Improve quality consistency and reduce fuel consumption.

Learn More

Real-time monitoring of CNC machines with production counts, spindle hours, cycle time, downtime tracking, and efficiency analytics for Industry 4.0.

Learn More

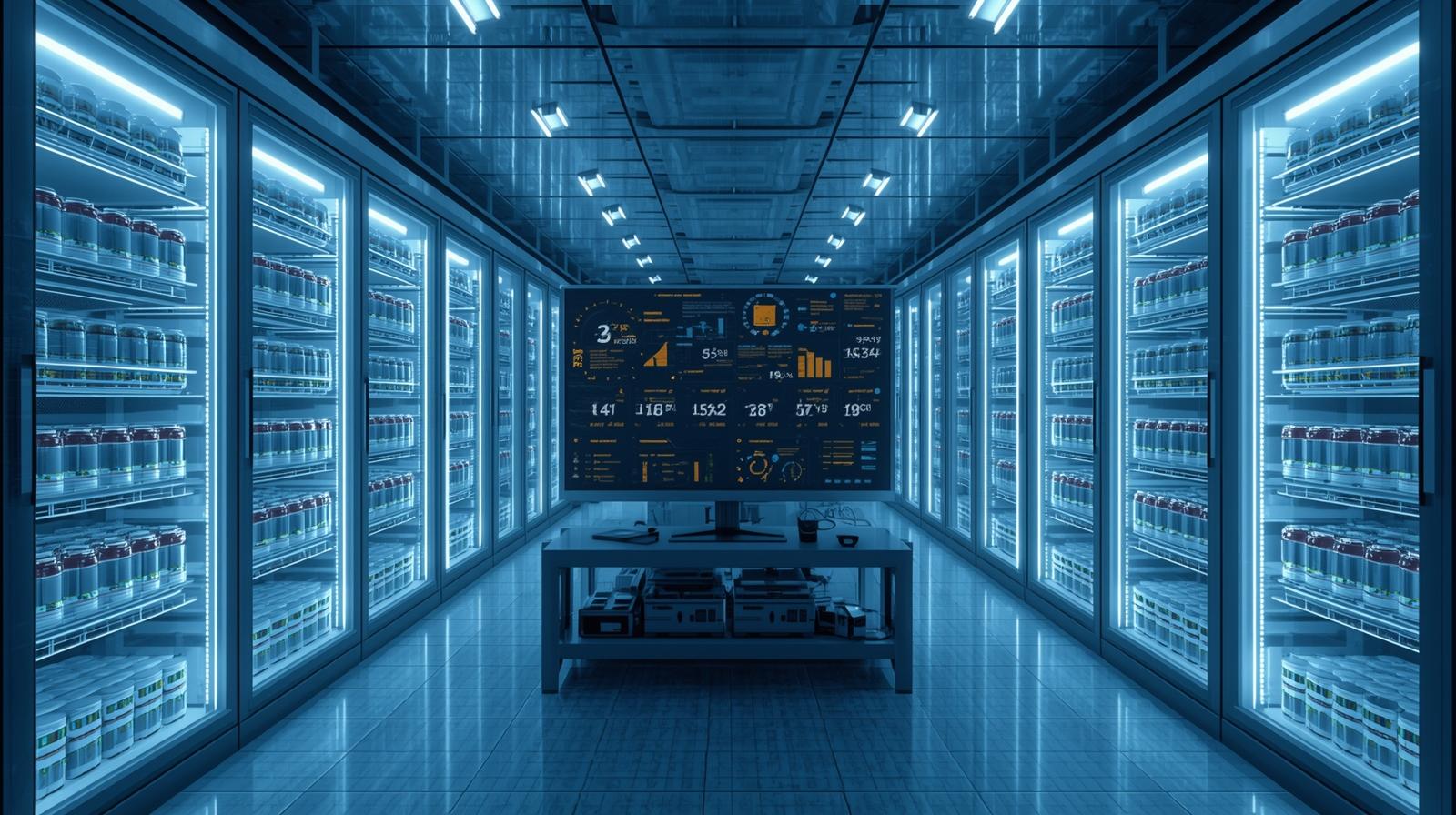

Monitor power, cooling, and environment conditions. Improve PUE, safeguard uptime, and optimize performance with role-based alerts.

Learn More

Track temperature, humidity, rainfall, air quality, and environmental parameters. Enable smarter planning for Solar & wind power forecast.

Learn More

Maintain temperature & humidity thresholds, manage door events, and safeguard product quality with automated compliance logs, energy efficiency, and safety.

Learn More

Ensure accuracy and compliance. Track calibrations, capture transactions, and integrate with MES/ERP for traceable operations.

Learn MoreThe Nu IO Platform is a next-generation Industrial IoT data acquisition and analytics solution designed for Industry 4.0-ready factories. It connects seamlessly to machines, sensors, PLCs, and enterprise systems — enabling real-time visibility, predictive insights, and process optimization.

Create powerful industrial dashboards in minutes — no coding needed. Add charts, gauges, KPIs, and process visuals with real-time, color-coded alerts. Works seamlessly on desktop, mobile, and control room screens. Easily connect to PLCs, SCADA, IoT devices, or databases for instant visualization. Customize layouts with drag-and-drop widgets to match your industry’s unique workflows

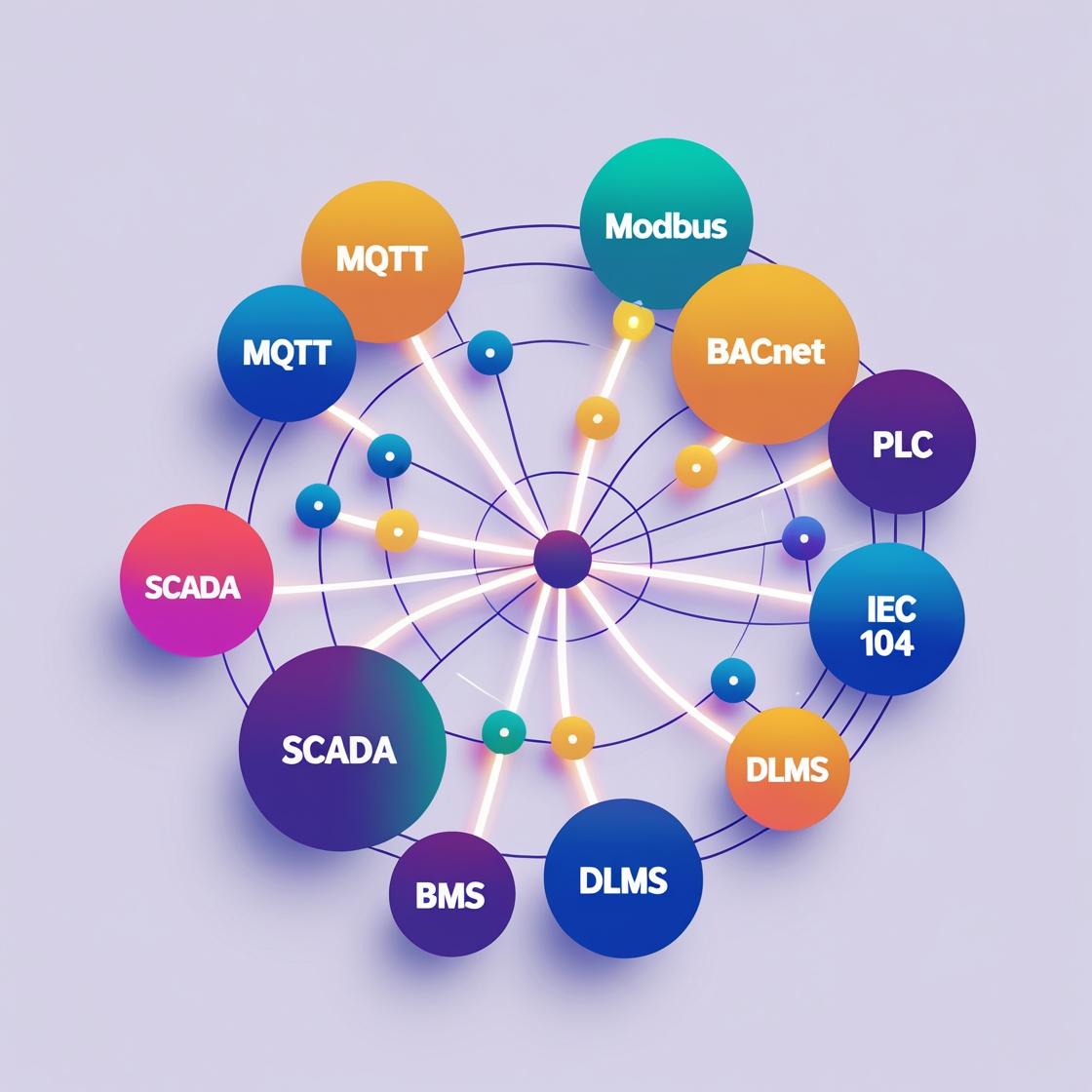

Seamlessly connect to any industrial device with built-in support for Modbus, OPC, MQTT, BACnet, Siemens S7, Allen-Bradley, Mitsubishi, Omron, and more. Auto-tag mapping ensures fast setup and full interoperability between legacy and modern assets. Future-ready architecture lets you scale effortlessly as new protocols and devices are introduced.

Generate automated or on-demand reports with AI-powered trend analysis for predictive insights. Pull data directly from connected databases, export in PDF, Excel, or CSV, and schedule email reports or SMS alerts for critical parameters to keep decision-makers instantly informed. Role-based alerts ensure the right people get the right information at the right time.

Process and analyze data right at the source with high-performance industrial edge devices. Reduce latency, improve reliability, and enable real-time decision-making — even without constant cloud connectivity. Securely connect to machines, sensors, and controllers while running IIoT, AI, and analytics applications directly on-site.

The Industrial Gateway for Every Protocol

High-performance Ethernet gateway with MQTT, Modbus, BACnet, DLMS, and more. Bridges legacy and modern systems, stores data during outages, and ensures secure, real-time connectivity for IIoT, edge analytics, and remote control.

Reliable IIoT Data Over Cellular

Industrial-grade 4G-LTE modem with built-in Modbus RTU/ASCII to MQTT gateway. Enables secure, remote data acquisition from field devices to cloud platforms, ensuring continuous monitoring in locations without wired connectivity.

Long-Range Wireless for IIoT

High-performance LoRa gateway for reliable, long-range communication between remote sensors and central IIoT platforms. Supports multi-protocol integration, local data storage, and secure cloud connectivity.

Proudly delivering IIoT and AI-powered solutions to leading industries worldwide.